Kencoa satisfies both domestic

and overseas customers with stable

quality control capabilities

and cost competitiveness.

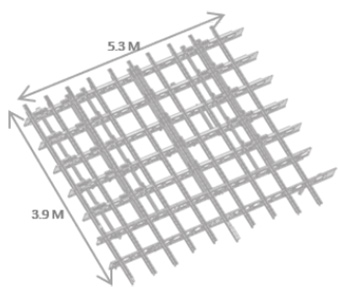

With more than 20 years of precision machining and sheet metal know-how recognized by customers,

Kencoa Group supplies aircraft structure and assemblies as Tier1.

It specializes in manufacturing difficult-to-cut materials

such as steel and titanium and has several long bed machining equipment capable up to 20M long bed parts.

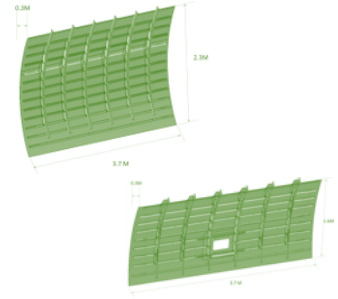

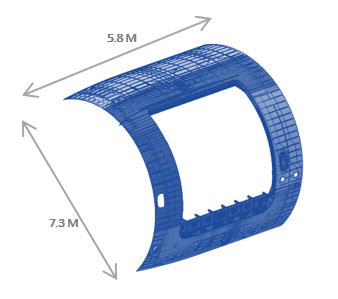

It is possible to fully assemble a small aircraft that includes not only structure assembly,

but also engine installation and wire harness.

Since Kencoa Group operates a Raw Material Distributor, direct supply of aerospace materials required for

manufacturing parts is a differentiated service unique to Kencoa that can enhance price competitiveness.

COMMERCIAL AEROSPACE PROVEN EXPERIENCE

· Airbus Freighter Conversion: 330, 320, 321

· Boeing 737, 747, 757, 767, 777, 787

· Airbus 320, 350

· Korean Airlines Fleet Services MRO

· Full 3D CAD Model Based Definition (MBD) and Digital Product Definition (DPD)

BUSINESS AVIATION PROVEN EXPERIENCE

· Gulfstream G280, G450, G500/600, G550, G650

· Bombardier Challenger

· Mitsubishi Regional Jet (MRJ-200)

· Hawker Beechcraft

ENG

ENG